Management of pneumatic energy resources in compressed air systems.

" Make your compressed air work at maximum efficiency "

We optimize the performance of your pneumatic systems to reduce losses, anticipate failures, and achieve energy savings at the source.

Is your compressed air system running inefficiently without you even knowing?

Most industries don’t detect energy losses in their pneumatic systems until it’s too late. Invisible leaks, oversized or poorly maintained compressors, inadequate maintenance, and poor configurations lead to high electricity costs, production downtime, and a loss of competitiveness.

“Discover a comprehensive solution to manage your air intelligently with our services.”

40%

Generated compressed air is lost through undetected leaks.

Concrete benefits for your operation

Up to 30% immediate energy savings.

Reduced downtime and unexpected stoppages.

Improved maintenance and operational metrics.

Compliance with efficiency and sustainability standards.

Extended useful life of critical assets.

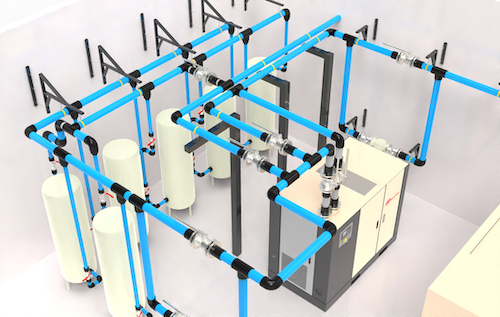

Products involved

- Compressors | Ingersoll Rand

- Dryers & Filters | Protection of Pneumatic Systems

- Aluminum Piping | Custom Technical Installation

- Spare Parts | Maintenance Kits, Valves, Filters

- Nitrogen Generators | Pure and Enriched Nitrogen Gas

All equipments have

“With SWEM’s pneumatic diagnosis, we cut maintenance downtime by 59%. They detected invisible leaks that were costing us far more than we ever imagined.”

– Maintenance Manager, Food Industry